Different Types of Water Pump Seals

Elastomer Rubber Bellow Mechanical Seals

Developed with rubber bellow, these types of pump seals is widely used for water, oil and other light duties applications. Both standard and OEM elastomer bellows seals are available.Most of our rubber bellow seals can easily replace your pump seal.

Metal Bellow Mechanical Seals

PTFE Teflon Bellow Mechanical Seals

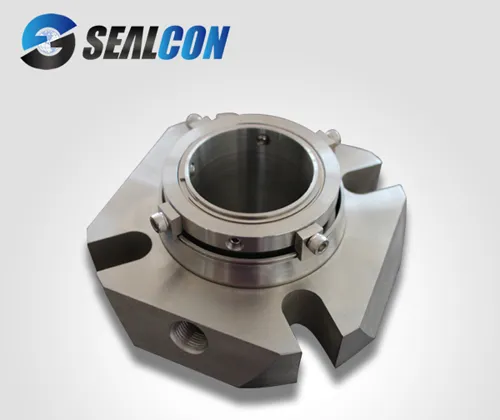

Single Cartridge Seals

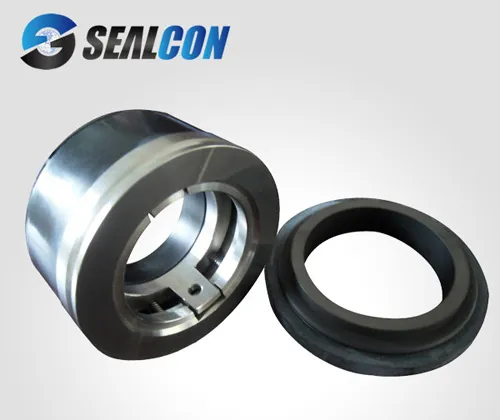

O Ring Mechanical Seals

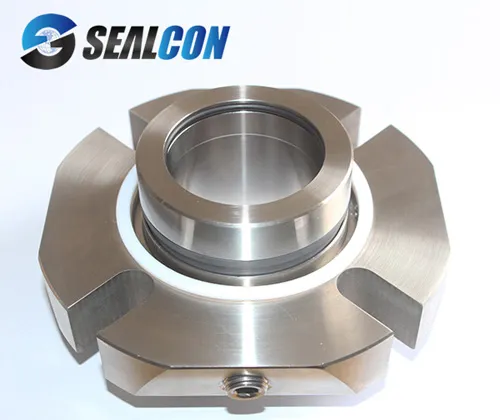

Double Cartridge Mechanical Seals

PTFE Wedge Mechanical Seals

Flygt Mechanical Seals

O.E.M Mechanical Seals

Stationary Seats

Mechanical Seal Working Principle

The working principle of mechanical seal for pump is to form the thin liquid film between rotating ring and shaft, so that it can efficiently prevent leakage of medium and make the end face lubricated, which help achieve the sealing effect. These types of pump seals are often used in rotating machinery, such as pumps, compressors, and reaction stirred kettle.

Mechanical Seal Function in Pump

There are 2 common sealing methods of the pump: mechanical seal and soft packing seal. Each of them has different characteristics and they are also suitable for different occasions. The correct selection of mechanical seals is beneficial to reducing the cost and improving the working efficiency.

Compared with the soft packing seal, the types of mechanical seal for pump has the following advantages:

1. Good sealing function: In the long working, the sealing state of mechanical seals for pump is very stable, and the leakage is small: about 1% of the leakage of soft packing seal;

2. Long service life:The general service life can reach more than 1~2 year when used in oil and water working occasions; and the mechanical seals should have 6-months service life when used in chemical medium;

3. Small consumption of friction power:The friction power of mechanical seals for pump is only 10% ~ 50% of the soft packing seal. And the abrasion of the shaft or sleeve can be negligible;

4. Long maintenance period:The mechanical seals for pump can still meet the requirements of usage, even thought its end face is in a certain range of repair;

5. Good earthquake resistance:It is not sensitive to the vibration of the rotating shaft.

Mechanical seals for pump have complex structure, higher requirements and cost. And the operators needs to have a certain level of technology, such as the basic knowledge of fitter and the characteristics of the types of pump seals.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska