CLOSE

Search

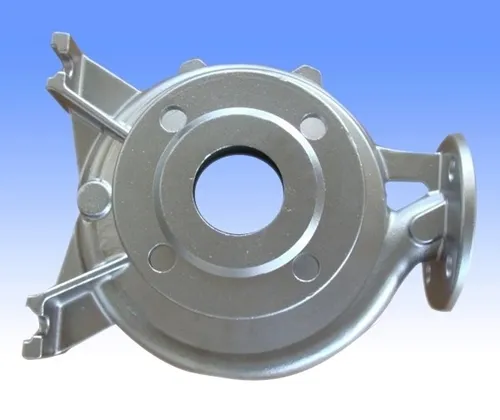

Closed impeller: consists of the blade and the front and back cover plate. Closed impeller, mostly used in centrifugal pumps, is more efficient and difficult to manufacture and is suitable for conveying water, solution and other less sticky liquid without particles.

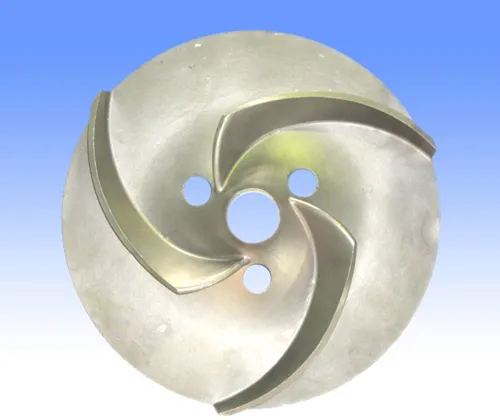

Semi-open impeller: generally there are two kinds of structure: the first part is the first half open type, which consists of the rear cover plate and the blade. The impeller efficiency is lower, and the sealing ring with adjustable clearance can be used to improve the efficiency. The other half is the open impeller, which is composed of front cover and the blade. As the sealing ring efficiency of the closed pump impeller is basically same as that of the closed impeller, with the sealing function of the back blade or the auxiliary impeller, the semi-open impeller is suitable for conveying liquids containing suspended solids such as solids and fibers. Since the semi-open impeller is difficult to manufacture, low to cost and strong to adapt, the application of centrifugal pump in refining and chemical industry has been gradually increased in recent years. And it is used for conveying water and similar liquid.

Open impeller: it only has the blades and blades are strengthened. The pieces of open impeller blades are 2-5. The pump impeller is low in efficiency and has less application. It is mainly used to transport the liquid with higher viscosity and the slurry liquid.

The rear curved blade. The blades are cylindrical and twisted. The twisted blades can reduce the load of the blades, improve the suction performance of the centrifugal pump and improve the anti-cavitation capability. But the manufacturing is difficult and the cost is high.

Get In Touch With SEALCON

Want the mechanical seals price list? Fill out the form and we'll get back to you ASAP.

Related Products

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska