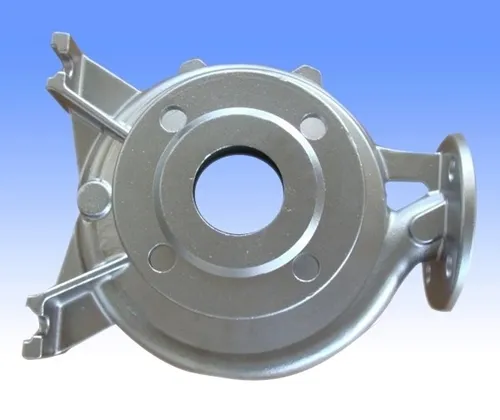

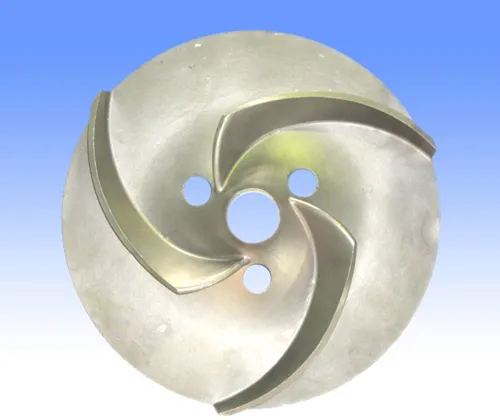

Classification of pump spare parts

Generally, there are the impeller, bearing, sealing device, sealing material, main shaft, key, inducing wheel and other materials.

A pump is a machine that carries liquid or pressurizes the liquid. It transfers the mechanical energy of the original motive or other external energy to the liquid to increase the liquid energy. It is mainly used for conveying liquids including water, oil, acid lye, emulsion, suspension-emulsion and liquid metal, etc., it also can transport liquid, gas mixture and liquid containing suspended solids. The technical parameters of pump performance include flow, suction, lift, shaft power, water power, efficiency, etc. According to different working principles, it can be divided into volume water pump, vane pump type. The volumetric pump uses the change of its studio volume to transmit energy; Vane pump is used to transfer energy through the interaction of rotary blades and water, with the centrifugal pump, axial flow pump and mixed flow pump.

Classification of water pumps

1. According to the direction of the pump shaft, it can be divided into the horizontal pump, vertical pump and inclined pump.

2. According to the shell type, it can be divided into the radial split water pump and axial split water pump.

3. According to series, it can be divided into single-stage pumps and compound pumps.

4. In the form of suction, it can be divided into the single suction pump and double suction pump.

5. According to the water pump, it can be divided into the central supporting water pump, pipe type water pump, co-seat pump, split water pump and removable water pump.

6. According to the driving mode, it can be divided into direct connection, gear transmission, hydraulic coupling transmission, belt transmission and coaxial type.

7. According to special structure, it can be divided into liquid-type, cylindrical, double-wall shell type, ground pit drum type, extraction type, self-priming, submerged type and shielding type.

8. According to the axial force balance, it can be divided into balanced drum pump, balanced disc pump, self-balancing pump and balanced hole pump.

9. According to different purposes, it is mainly divided into boiler feed pump, circulating pump, sewage pump, impurity pump, sand pump, slurry pump, sewage pump, fresh water pump, fire pump, booster pump, corrosion resistant pump

10. According to the material, it can be divided into cast iron pump, stainless steel pump, plastic pump, fluorine plastic pump, engineering plastic pump.

11. According to the structure, it can be divided into the centrifugal pump, diaphragm pump, gear pump, plunger pump, reciprocating pump, vacuum pump and injection pump.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska