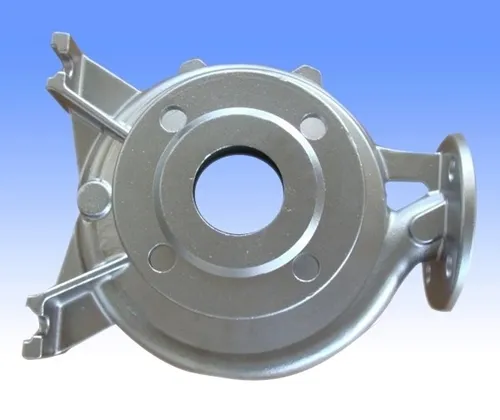

Pump body: including suction chamber and the pressure chamber.

Suction chamber: its function is to allow the liquid to flow evenly into the impeller.

Pressure chamber: its function is to collect liquid and send it to a lower impeller or guide discharge pipe. At the same time, reduce the velocity of the liquid, so that the kinetic energy becomes pressure energy. The pressure chamber has two forms: volute and guide wheel. The volute is named for the spiral shape of the runner. The liquid flows along the spiral line. With the increase of the flow section, the velocity decreases and the kinetic energy becomes pressure energy.The guide wheel is commonly used in the segmented multistage pump. In order to make the structure simple and compact, the guide wheel is used to transform the energy between the primary impeller and the secondary impeller, and the liquid flows along the flow path specified by the guide wheel to the inlet of the secondary impeller.

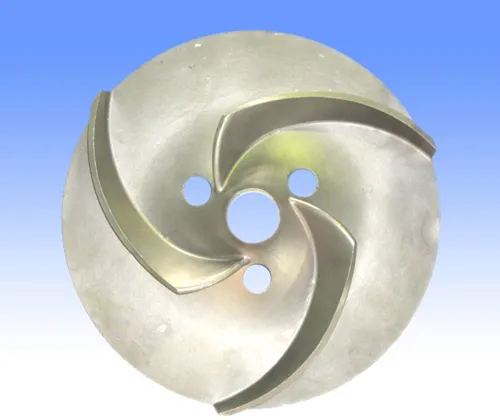

Impeller: it is the only element in the centrifugal pump to transfer energy to the liquid. The pump allows the mechanical energy to become the pressure of the liquid to increase the pressure of the liquid. The impeller is fixed on the shaft with the key, and the shaft is rotated by the original motive, passing the energy of the original motive to the liquid through the blade. According to the liquid flow impeller channel classification, it can be divided into single suction impeller (have an entry in the side of the impeller) and double suction impeller (liquid from symmetrically on both sides of the impeller flow in the impeller passage). According to the main flow direction of the liquid relative to the axis of rotation, the impeller can be divided into radial flow impeller, axial flow impeller and mixed flow impeller. According to the structure of impeller, it can be divided into the closed impeller, open impeller and semi-open impeller. The closed impeller consists of a number of blades and the wheel cover and wheel disk on both sides. The space between two adjacent blades and wheel cover and wheel disk is the flow path of the liquid. Open impeller only has the blade, without wheel cover and wheel; Half open impeller only is a wheel on one side of the blade.

Shaft: it is an important part of the transmission of mechanical energy. The torque of the original motive is transmitted to the impeller through it. The pump shaft is the main part of the pump rotor, the shaft is equipped with the impeller, axle sleeve, balance plate and other parts. The pump shaft is supported by both ends of the bearings, which is high-speed rotary in the pump. Therefore, the pump shaft should be capable of bearing capacity, abrasion resistance and corrosion resistance. The material of the pump shaft is usually made of carbon steel or alloy steel.

The seal ring is a sealing device installed between the rotating impeller and the stationary pump case (a combination of middle and guide leaves). Its function is to increase the resistance of liquid flow between high and low-pressure cavity in the pump by controlling the gap between them and reduce leakage.

Shaft sleeve: the shaft sleeve is used to protect the pump shaft from corrosion and wear. If necessary, the axle sleeve can be replaced.

Shaft seal: the stuffing box between pump shaft and front and rear cover is referred to as shaft seal, mainly preventing liquid leakage and air entering the pump, so as to seal and prevent the pump from cavitation caused by air intake. There are three types of shaft seals: rubber seal with the skeleton, packing seal and mechanical seal.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska